研发设计

“佛山市铝合金挤压型材模具设计工程技术研究开发部门”是由兴顺公司与佛山市的有关部门共同组建成立的,由二十多名包括博士、高级工程师等高中级技术职称的专门技术人员组成,研究开发各种铝型材模具相关设计制造项目,如:与华南理工大学共同研发的广东省教育部产学研项目“铝型材挤压模具数字制造关键技术”,粤港关键领域重点突破项目“大型复杂精密型材挤压模具的设计制造关键技术”等。

型材挤压模拟有限元分析技术

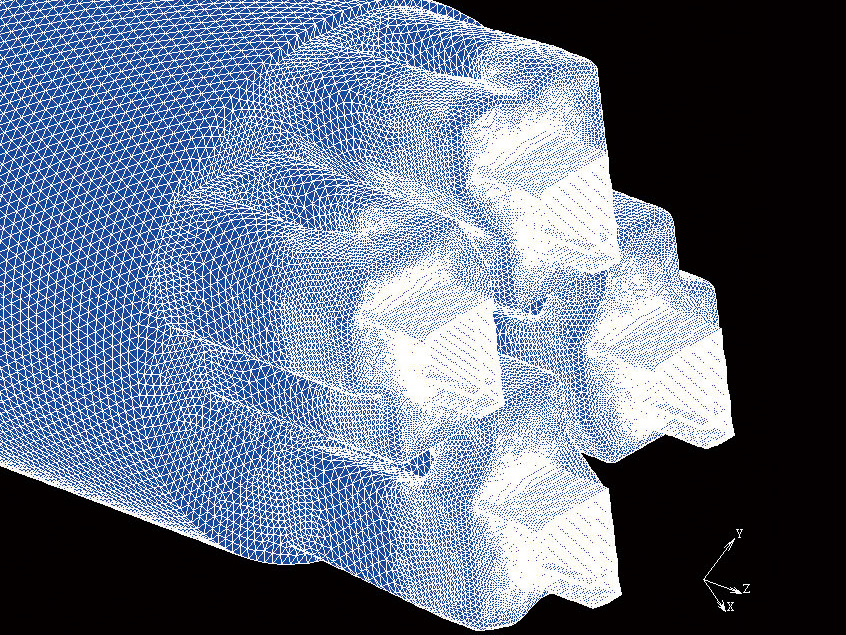

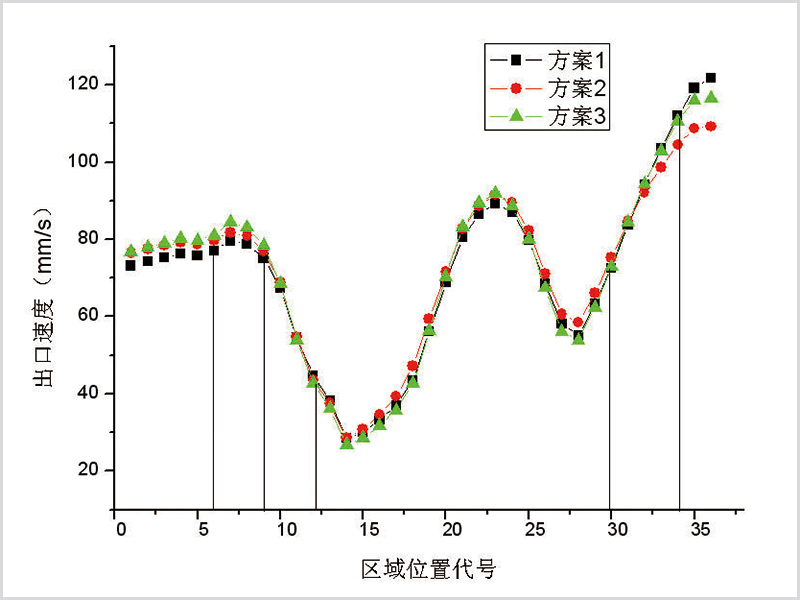

自2006年起,兴顺与华南理工大学合作,自主研发型材挤压模拟有限元分析技术。结合华南理工大学的研究理论与兴顺模具十多年来的生产实践经验,共同开发出铝型材挤压模具试验软件,现此技术已日渐走向成熟并开始使用于实际生产中,能够通过数据和参数优化模具设计,提高模具上机合格率,提高模具质量。

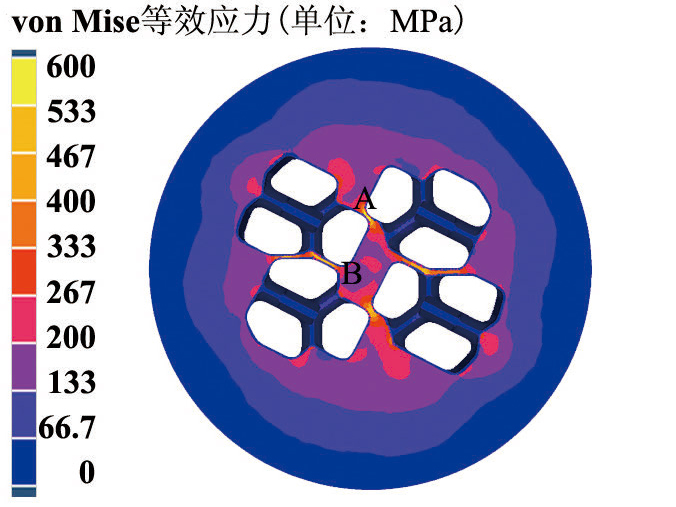

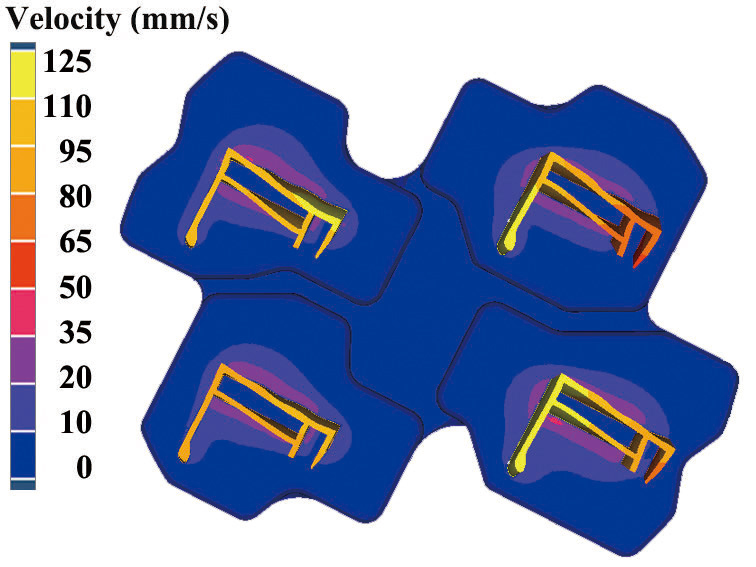

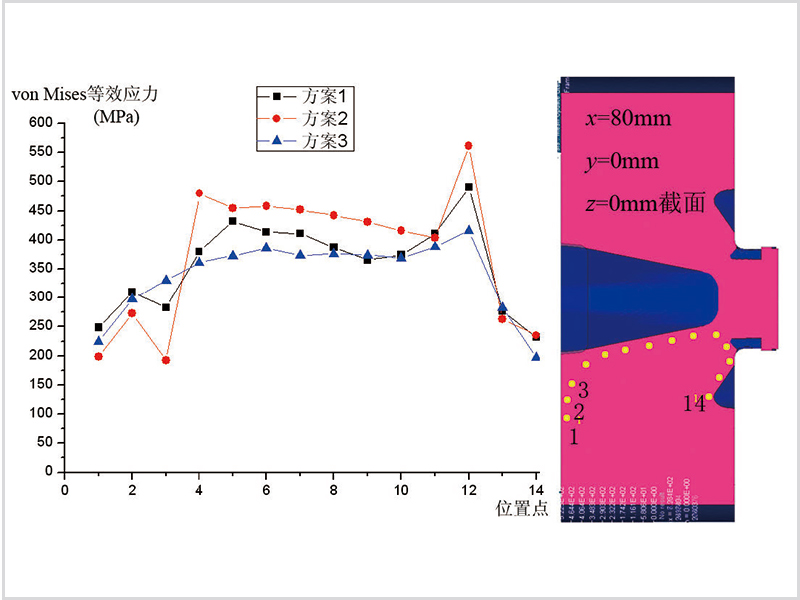

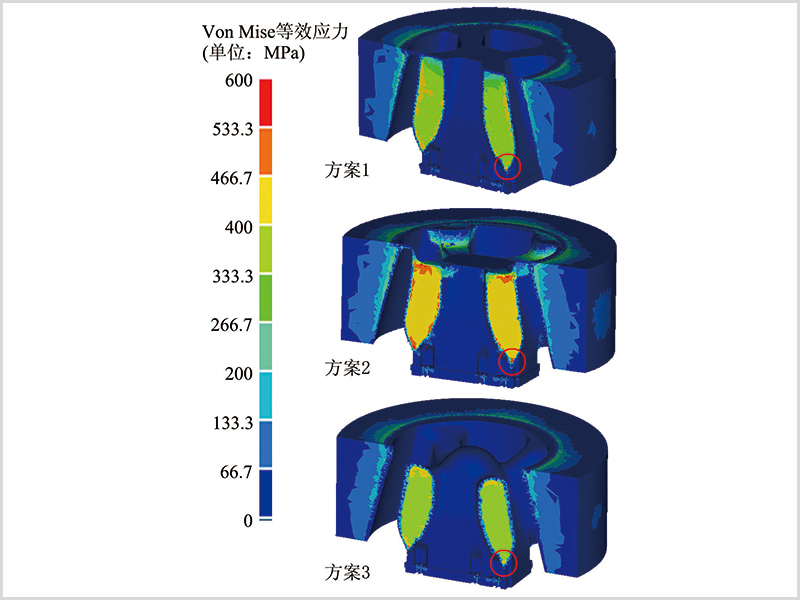

通过对铝型材挤压工艺的数学、几何与力学建模,模拟仿真铝型材挤压过程,可以清晰明了地显示挤压过程中坯料的分流、焊合与成型过程,以及挤压过程中各力学与物理参数的动态分布,包括材料质点流动速度分布、温度分布、应力分布、以及挤压力分布等参数。

{"serList":[{"icon":"iconfront front-shouye","status":"1","isSys":"1","title":"首页","url":"index.html","type":"index"},{"title":"产品","icon":"iconfront front-daohang","type":"link","isSys":"0","status":"1","linkData":"{\"linkType\":\"1\",\"linkName\":\"模具产品\",\"linkKey\":\"page\",\"linkUrl\":\"product.html\",\"jsonData\":{}}","url":"product.html"},{"icon":"iconfront front-weibiaoti-","status":"1","isSys":"1","title":"电话","phone":"13800138000","type":"tel"},{"icon":"iconfront front-pinglun","status":"1","isSys":"1","title":"留言","url":"msg.html","type":"msg"},{"icon":"iconfront front-didianmianxing","status":"0","isSys":"1","title":"地图","url":"map.html","type":"map"},{"icon":"iconfront front-duanxin","status":"0","isSys":"1","title":"短信","phone":"13800138000","type":"sms"},{"icon":"layui-icon layui-icon-share","status":"0","isSys":"1","title":"分享","shareList":["weixin","weibo","qq","qqZone","douban","tieba","copy"],"type":"share"}],"hasEdit":true}